Just in time for lockdown, I made it home in the laps of the Himalayas. With everything at a halt even in this small village close to Dharamshala, I decided to start building a cob oven. With two pair of hands at play and some guidance, the sculpting began. From digging the mud, making the mix, acquiring material, applying the cob, juggling amongst household chores, a day job and the omnipresent mosquitoes I built an oven (with the help of a few friends) that we can now say is almost complete. Sharing some process pictures here.

The beginning. The source of the oven. This ditch is now big enough to fit a cow.

Foundation

A flat platform with the local jhaadu (broom)

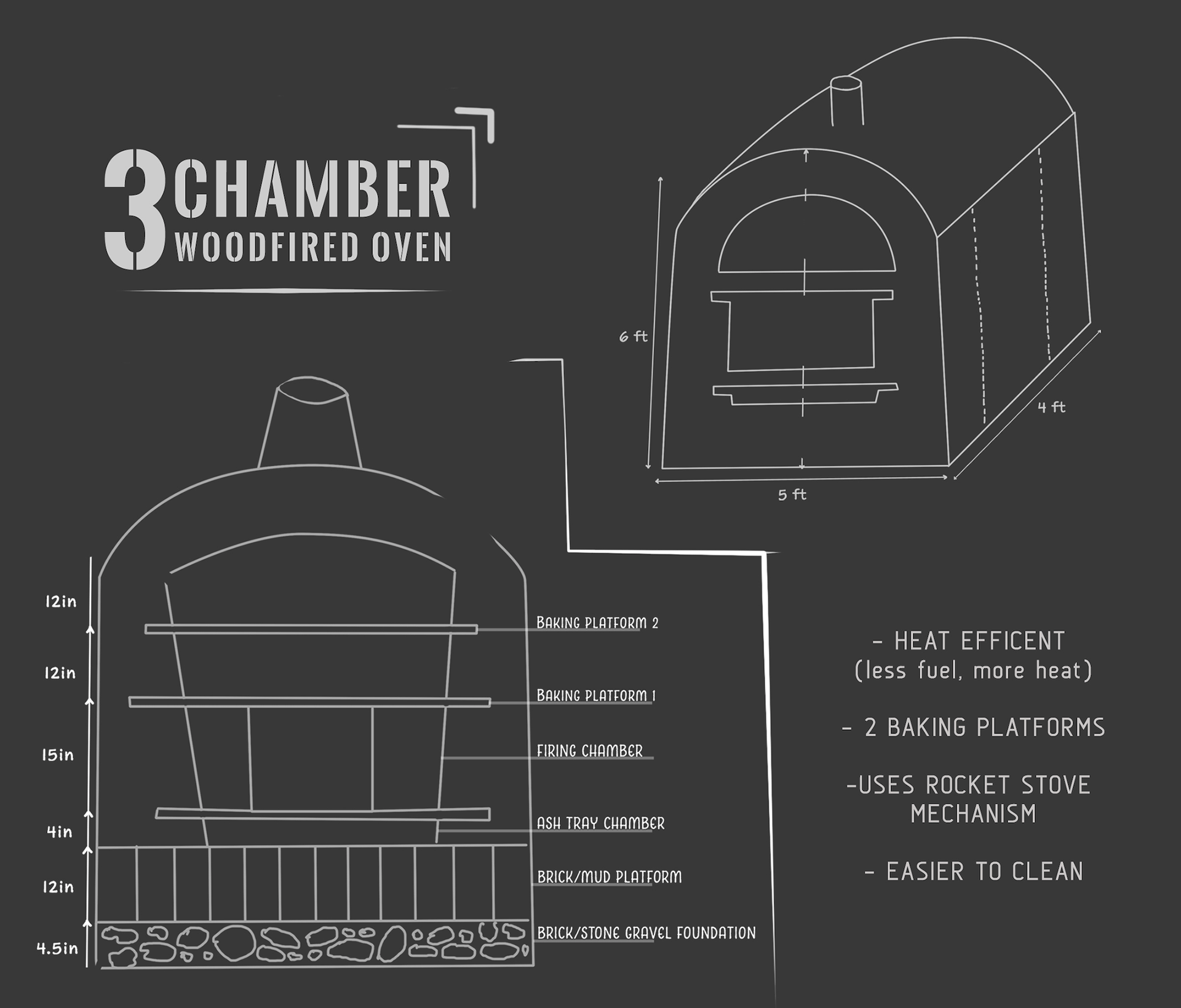

Forming the first chamber of oven - The Ash collection Chamber

The second chamber - The Firing Chamber

The front walls of the firing chamber have two pipes that will help take the cold air in, much like how a rocket stove works.

The baking chamber platform - The cardboard is simply a mold that can temporarily hold the weight till the materials dry. Once the oven is fired it will burn off.

The cardboard doesn't cover all the area of the baking grid. The sides have been left open as vents to let the hot air to the baking chamber.

The final day - Building the dome

Both the baking and firing chambers have doors. The doors of the oven were made using spare metal frames and 1/2 inch mesh stretched between the frame. Mud was then applied on one side of the mesh. This helped tremendously to keep the heat inside.

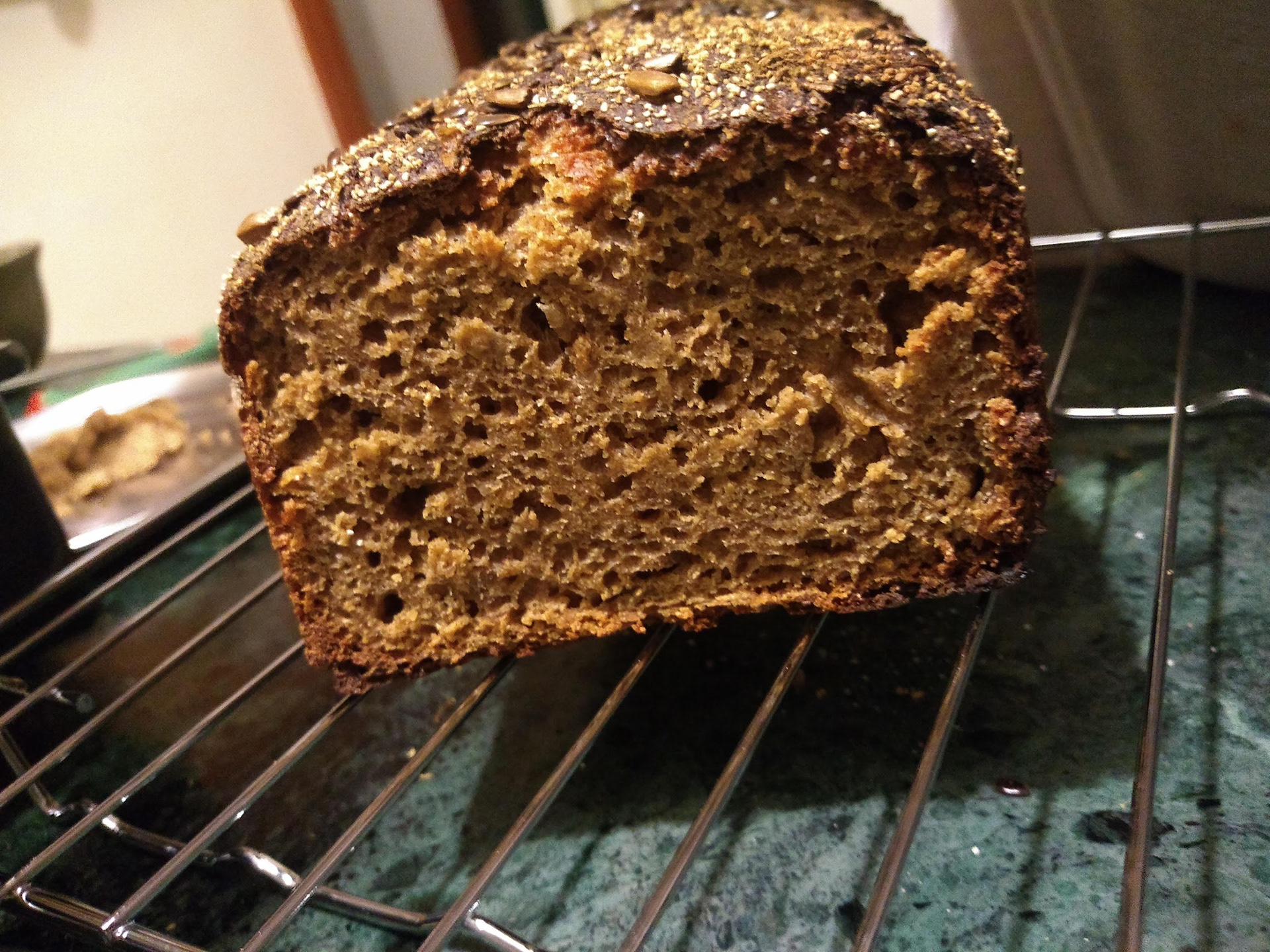

The first firing - Baking the Baker

The materials used to make this oven include:

- Mud from the farm

- Hay | Pine needles (from nearby forest)

- Cowdung

- Cow urine

- Bricks

- Metal rods (collected from scrap)

- Starch (made at home from white flour (maida) or sometimes rice

- Sand for temporary use

- Ash (collected from households or naan-chole walas nearby

All materials used were collected or dug from around the house and farm. Hardly any material was bought at the store. We tried our best to make an oven that would be completely natural and local. For a few parts of the project we included local carpenter and metal workers. Including their services and a few tools we bought at the market we ended up spending a total of 650 rupees on building the oven and below is the fruit of that. :)